Contents

Nowadays, Fibre optic broadband has been a new way to connect Internet. It can keep high speed in long-distance data transmission. But do you know knowledge about fiber optics, fiber-optic cables, and fiber connectors? This article will mainly walk you through detailed information about fiber connector types.

What is Fiber Optics?

Fiber optics is the technology that transfers information with a pulse of light through glass or plastic fiber. Optical fibers are bundled into a cable to carry light and this cable is called fiber-optic cable. It is known that fiber optics cables can be classified into single mode and multimode. Fiber optics can be applied in long-distance telecommunication. It is also used to provide home and office with fiber optic Internet connection, phone, and other services.

What is an Optic Fiber Connector?

An optic fiber connector is used to connect two ends of optic-fiber cables. It allows for quick connection or disconnection of optic fiber cables without splicing. Optic fiber connectors usually feature a ferrule that helps keep the fiber in place and align strands of fibers to pass the light. A fiber connector is considered an important part of an optic-fiber cable. It plays an important role in stable optic fiber transmission.

There have been many types of fiber connectors on the market since the 1980s. And at that time optic fiber connectors may be difficult to use, but nowadays, it has been upgraded to be more convenient to use.

Structure of Fiber Connectors

Different types of fiber connectors feature different structures, but they mainly have four main important parts: ferrule, connector, an attachment mechanism, and boots.

The ferrule is the core part of the fiber connector, which allows for the alignment of optic fibers with accuracy. It is usually made of plastic, metal, ceramic, and glass. The connector body helps support the ferrule and shield the optic fiber cables and this part is usually made of metal or plastic. The attachment mechanism makes the way to connect the connector body and optical equipment. In addition, the boot functions as a protector for optic fiber cable.

Take the SC connector as an example, it is composed of the dust cap, connector housing, connector sub-assembly, ferrule, crimp eyelet, and boots. The SC connector features a fiber ferrule, the diameter of which is 2.5mm. The connector sub-assembly is used to keep the fiber and cable in place and it is covered by connecting housing. The crimp eyelet increases the strength of connecting mechanism to protect the fiber inside. What’s more, the boot is designed to protect optic fibers from external damage.

Optic Fiber Connector Types

There are more than one hundred kinds of optical fiber connectors on the market. They come in different types according to polishing methods, booth length, and transmission media. But here we will only talk about the most common fiber connector types: SC, LC, ST connectors, FC, and MPO/MTO connectors. These five types of optical fiber connectors can mainly represent the optic fiber market.

SC Connector

SC is the abbreviated name of the standard connector. It is also called a square connector or subscriber connector. SC (standard connector) features a 2.5mm ferrule. It was introduced by Nippon Telegraph and Telephone and it has been widely used today thanks to its low cost and quick push-pull structure. SC is the most common choice for PON (passive optical network) and converters. Many people also prefer standard connectors rather than ST connectors in telecommunications.

LC Connector

LC means lucent connector or little connector, which features a 1.25mm ferrule. It is a type of small form factor connector (SFF connector). It was developed by Lucent Technologies. It also features a push-and-pull design. Because of their tiny size, LC is very suitable for high-density installation in FTTH and panels. LC connectors can be divided into simplex and duplex structures. LC connectors also have polarized design for stable transmission.

ST Connector

ST (Straight Tip) connector looks like an FC connector at the first glance. It was created by AT&T, featuring a 2.5mm ferrule. ST connector was introduced by AT&T and designed for multimode fibers. It is easy to operate thanks to its spring-loaded design. ST connectors are widely used in both long and short distance applications such as office and campus fiber applications and network applications.

FC Connector

FC connector is the first ceramic-shaped connector. It usually features a screw-look housing made of stainless steel or nickel plating. The alignment key and screw-design motion make the FC connector great for single mode fibers and in an environment full of vibration. It has been widely used in fiber optic networks in the past but has gradually been replaced by other connectors in recent years.

MPO/MTP Connector

You may also hear MPO or MTP connectors, which have been very popular in recent years. It is a connector that can combine 12 to 24 fibers in a single ferrule. In addition, it supports 40G and 100G parallel fiber connectivity. MPO/MTP connectors are used in high-density network cabling systems, e.g. data centers.

How do I Choose Fiber Connectors?

Before choosing fiber connectors, you should know that they are used to connect fiber optic cables.

Fiber Optic Cables

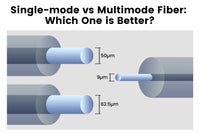

There are two basic types of fiber optic cables: single mode and multimode. Is your fiber optic cable single mode or multimode? Single mode fiber optic cable allows for one light mode to propaganda at one time, while multimode means that multiple light modes can pass through the fiber. The multimode also features a larger central core than the single mode to allow for different rays of light. You can identify whether the cable is single mode or multimode by the jacket color.

In general, the single-mode cable comes with a yellow or blue jacket and a multimode cable feature an orange or green cover.

Fiber connectors also come in single mode and multimode. And single mode fiber connectors usually have blue or green covers, while multimode connectors feature beige covers. But different manufacturers may have different color choices, so you’d better verify it from the suppliers before buying. With the development of technology, many fiber connectors such as FC and LC are compatible with both single mode and multimode fibers.

Polish Types

Next, you should also consider polish types including PC Polish, UPC Polish, and APC Polish.

- PC Polish: PC polish is the original polish type. It looks like a flat fiber connector, but in fact, it is polished with physical contact. PC fiber connector features a slight cone design to reduce the air gap, achieving a lower optical return loss (ORL). The reflection loss of this polish type is about -40dB.

- UPC Polish: UPC means ultra physical contact, which is an advancement of PC polish. It has a better fiber surface finish than PC polish, so it has a lower optical return loss (ORL). UPC polish is commonly used in our daily life, great for TV, telephone, and network system. The reflection loss of this polish type is about -50dB. But please note that the lower optical return loss is affected by the quality of fiber surface polish, so you’d better choose fiber connectors from well-known suppliers.

- APC Polish: APC means angled physical contact and its ferrule end-face is polished at an 8 degree angle, resulting in a lower reflection loss. But when you choose an APC connector, you should pair it with other angled-polish connectors or it will cause high insertion loss. The ORL (optical return loss) of the APC connector is about -60dB or higher.

If you want to choose one connector for a high-precision optical fiber application, APC is your first choice. But if you don’t need a so precision optical fiber signaling, UPC is great for most optical fiber applications.

Termination Types

There are many types of connector terminations. Should you choose epoxy and polish termination or quick termination connectors? It depends on the installation quality and cost. Let’s take a look at some of your options.

- Epoxy and Polish Termination: This traditional termination type is chosen by most people. The ferrule is bonded with epoxy and the end is polished with a thin film. This kind of termination takes longer to install but offers high quality, low cost, and excellent stability.

- Pre-Polished Termination: This type of connector features a pre-polished fiber end inside the connector body and you only need to strip your fiber, and then cleave and insert it into the connector body. It is a quick termination but can be a bit expensive.

- Anaerobic Termination: In anaerobic termination, the fiber connector features a quick-setting glue. Because the glue can not withstand water or high temperatures, it is only suitable for indoor fiber optical applications.

All in all, you need to know what equipment the fiber connector will be plugged into and what fiber optic cables you will use and then choose the best fiber connector. If you are still confused about choosing the right type of connector, you can take a look at the following chart.

| Types of Connector | Coupling Mechanism | Polishing Type | Applications |

| SC | Bayonet | PC/APC/UPC | CATV, PON, and Converters |

| LC | Bayonet | PC/APC/UPC | FTTH |

| ST Connector | Bayonet | PC/UPC | Telecommunication |

| FC Connector | Screw-look | PC/APC/UPC | Network Connections |

| MPO/MTP Connector | Push-Pull | APC/UPC | Data Center |

For more information on this topic, you can keep up on our blogs. While VCELINK offers general and basic information for our customers and other visitors to the website, it’s not professional advice.

Be the first one to comment.

Leave a comment